DESCRIPTION

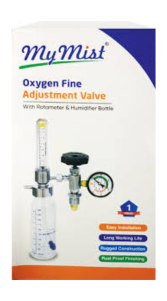

If you’re looking for a breakdown of the Mist Oxygen Fine Adjustment Valve (often used in medical, aquarium, or industrial oxygen setups), you’re dealing with a precision instrument designed for “micro-metering.”

Since these valves are built for high-stakes environments where flow consistency is everything, here is a breakdown of what makes them tick.

Core Specifications & Features

The “Fine Adjustment” label isn’t just marketing; it refers to the needle-valve design inside that allows for incremental changes that standard ball valves can’t handle.

-

Needle Valve Precision: Uses a long, tapered needle to provide linear flow control. This means turning the knob results in a predictable, tiny change in oxygen volume.

-

Material Integrity: Usually constructed from nickel-plated brass or stainless steel to prevent oxidation and ensure “Oxygen Clean” standards (essential to avoid combustion risks).

-

Pressure Rating: Most are designed to handle input pressures from a regulator and down-regulate them to a stable output, often measured in Liters Per Minute (LPM) or bubbles per second (for aquatic use).

Why the “Mist” Designation?

In most contexts, the “Mist” refers to the valve’s ability to facilitate nebulization or atomization.

-

Medical/Therapy: It controls the flow precisely enough to turn liquid medication into a breathable mist without fluctuating the dosage.

-

Aquatics/Hydroponics: It manages the “fine mist” of oxygen or CO2 bubbles, ensuring they are small enough to dissolve into the water rather than just floating to the surface and escaping.

-

Reviews

There are no reviews yet.